Mechanical Engineering: An Overview

Mechanical Engineering is one of the broadest and oldest branches of engineering, focusing on the design, development, production, and maintenance of mechanical systems. It involves applying principles of physics, mathematics, and material science to create solutions that address the mechanical aspects of design, production, and operation. Mechanical engineers work with machines, tools, engines, thermal systems, robotics, and manufacturing processes. This field covers a wide variety of industries, including automotive, aerospace, energy, manufacturing, robotics, and more.

- Key Aspects of Mechanical Engineering

- Core Areas of Mechanical Engineering

- Mechanical Engineering Process

- Types of Mechanical Engineering

- Applications of Mechanical Engineering

- Tools and Techniques in Mechanical Engineering

- Top Mechanical Engineering Programs

- Career Opportunities in Mechanical Engineering

- Salary Expectations for Mechanical Engineers

- Challenges in Mechanical Engineering

- FAQs About Mechanical Engineering

- Conclusion

Key Aspects of Mechanical Engineering

Aspect | Details |

Core Focus | The design, analysis, and manufacturing of mechanical systems and devices. |

Key Areas | Thermodynamics, mechanics, materials science, structural analysis, control systems, and automation. |

Objective | To design and optimize mechanical systems for efficiency, safety, sustainability, and performance. |

Challenges | Addressing sustainability, improving energy efficiency, designing innovative systems, and reducing environmental impact. |

Core Areas of Mechanical Engineering

Mechanics: The study of forces, motion, and energy. This includes both statics (forces in equilibrium) and dynamics (forces causing motion). It is essential for the design of mechanical components, machines, and structures.

Thermodynamics: Involves the study of heat energy and its transformation into other forms of energy. Mechanical engineers apply thermodynamics to design engines, refrigerators, and heating/cooling systems.

Materials Science: The study of materials used in engineering, such as metals, plastics, and composites. Mechanical engineers must choose the right materials for specific applications, considering factors like strength, weight, durability, and cost.

Manufacturing and Production: Focuses on methods of producing mechanical components and systems, such as machining, welding, casting, and additive manufacturing (3D printing). It also includes the design of production systems and processes.

Structural Analysis: Involves analyzing and ensuring that mechanical components and systems can withstand forces and stresses without failure. This area covers everything from bridges to mechanical parts in aircraft.

Fluid Mechanics: The study of fluid behavior, which is critical in systems like pumps, turbines, air conditioning systems, and hydraulic circuits.

Control Systems: The design of systems that regulate the behavior of mechanical devices, such as robotic arms, industrial machines, and automated manufacturing systems.

Robotics and Automation: Mechanical engineers design robots and automated systems that improve manufacturing processes, medical treatments, and even daily life.

Mechanical Engineering Process

Problem Definition: Engineers begin by understanding the problem or need, gathering requirements, and specifying the goals of the system or product to be designed.

Conceptual Design: A preliminary design is created, considering factors like performance, cost, materials, and environmental impact.

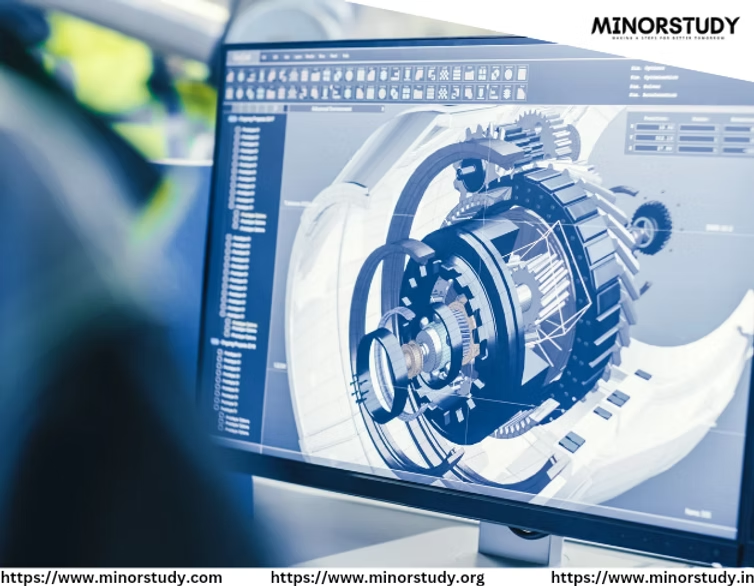

Detailed Design and Modeling: Detailed blueprints and 3D models are created using CAD (Computer-Aided Design) software. Simulations are often performed to predict how the design will behave under real-world conditions.

Prototype Development: Engineers create a prototype or model of the design, which is tested for functionality, safety, and efficiency.

Testing and Refining: The prototype undergoes various tests to evaluate performance, durability, and safety. The design is refined based on the results.

Production and Implementation: Once the design is finalized, it is manufactured, assembled, and deployed. Mechanical engineers oversee the production process to ensure quality control.

Types of Mechanical Engineering

Field | Description |

Automotive Engineering | Focuses on the design, development, and production of vehicles, including cars, trucks, and motorcycles. |

Aerospace Engineering | Involves the design of aircraft, spacecraft, and satellites, including propulsion systems and aerodynamics. |

Manufacturing Engineering | Focuses on developing and improving manufacturing processes, including automation and quality control. |

Thermal Engineering | Deals with heat transfer, engines, HVAC (heating, ventilation, and air conditioning) systems, and power plants. |

Mechatronics Engineering | Combines mechanical, electrical, and computer engineering to design smart systems like robotics and automation. |

Biomechanical Engineering | Applies mechanical engineering principles to biological systems, such as prosthetics, medical devices, and orthopedics. |

Energy Engineering | Focuses on the production, conversion, and efficient use of energy, including renewable energy systems. |

Applications of Mechanical Engineering

Application | Details |

Automotive Industry | Design and manufacture vehicles and vehicle components, including engines, transmissions, and safety systems. |

Aerospace | Design of aircraft, rockets, and space vehicles. Involves aerodynamics, propulsion systems, and materials engineering. |

Manufacturing | Development of processes and systems for producing consumer goods, machinery, and industrial products. |

Energy Systems | Design of systems for generating and utilizing energy, including power plants, turbines, and solar panels. |

HVAC Systems | Design of heating, ventilation, and air conditioning systems for buildings and industrial applications. |

Robotics and Automation | Design of robotic systems for manufacturing, medical, and defense applications. Includes control systems and sensor integration. |

Consumer Products | Design of products such as home appliances, tools, and electronic devices, optimizing functionality, safety, and cost. |

Tools and Techniques in Mechanical Engineering

CAD (Computer-Aided Design) Software: Tools like AutoCAD, SolidWorks, and CATIA are used to create detailed 3D models and blueprints for mechanical systems and components.

Finite Element Analysis (FEA): This technique is used to simulate how mechanical structures will respond to real-world forces, helping engineers optimize design for strength and durability.

CFD (Computational Fluid Dynamics): Software used to analyze the flow of fluids (liquids and gases) and how they interact with surfaces in mechanical systems, like in engines or airfoils.

CAM (Computer-Aided Manufacturing): Used in conjunction with CAD, CAM software helps control manufacturing processes like CNC machining and 3D printing.

Material Testing Equipment: Mechanical engineers use devices like tensile testers, hardness testers, and impact testers to measure the properties of materials.

Top Mechanical Engineering Programs

University | Country |

Massachusetts Institute of Technology (MIT) | USA |

Stanford University | USA |

University of California, Berkeley | USA |

Imperial College London | UK |

Georgia Institute of Technology | USA |

University of Cambridge | UK |

ETH Zurich | Switzerland |

National University of Singapore | Singapore |

Career Opportunities in Mechanical Engineering

Job Role | Responsibilities |

Automotive Engineer | Design and test vehicle systems, such as engines, transmissions, and safety features. |

Aerospace Engineer | Work on the design and development of aircraft, spacecraft, and propulsion systems. |

Manufacturing Engineer | Develop efficient manufacturing processes, optimize production lines, and integrate automation. |

Energy Engineer | Work on the design of systems for power generation, renewable energy solutions, and energy management. |

Thermal Systems Engineer | Design and optimize heating, cooling, and ventilation systems for industrial and residential applications. |

Robotics Engineer | Design robotic systems used in manufacturing, healthcare, and other industries. |

HVAC Engineer | Specialize in the design and installation of heating, ventilation, and air conditioning systems. |

Salary Expectations for Mechanical Engineers

Country | Average Annual Salary (USD) |

United States | $60,000 – $90,000 |

United Kingdom | £30,000 – £50,000 |

Canada | $50,000 – $85,000 |

Australia | $60,000 – $95,000 |

India | ₹4,00,000 – ₹8,00,000 |

Challenges in Mechanical Engineering

Challenge | Details |

Sustainability | Developing energy-efficient systems, reducing emissions, and creating sustainable manufacturing processes. |

Complexity of Designs | As technology advances, designs are becoming more complex and require sophisticated tools and expertise. |

Material Innovation | The need for new materials that offer greater strength, lighter weight, and lower cost while being environmentally friendly. |

Automation and Robotics | Integrating automation and robotics into industries while addressing challenges related to cost and complexity. |

Globalization | Managing manufacturing processes across multiple countries while ensuring quality and cost-effectiveness. |

FAQs About Mechanical Engineering

What is mechanical engineering?Mechanical engineering is the discipline that involves the design, development, and maintenance of mechanical systems. It integrates principles of physics, materials science, and thermodynamics to solve problems related to energy, motion, and force.

What skills are essential for mechanical engineers?Mechanical engineers need strong problem-solving skills, proficiency in CAD and simulation software, a solid understanding of thermodynamics and materials science, and the ability to think critically and analytically.

Where do mechanical engineers work?Mechanical engineers are employed in a variety of industries, including automotive, aerospace, energy, robotics, manufacturing, HVAC, and defense.

What education is required to become a mechanical engineer?A bachelor’s degree in mechanical engineering is typically required. Many engineers pursue advanced degrees (master’s or PhD) for specialization or advanced roles.

Is mechanical engineering a good career choice?Yes, mechanical engineering offers a wide range of career opportunities, competitive salaries, and the chance to work on innovative technologies that shape the world.

Conclusion

Mechanical engineering is a diverse and dynamic field with a vast range of applications. It combines knowledge from various disciplines to design and optimize systems that are essential for our daily lives, such as vehicles, machines, energy systems, and manufacturing processes. With the increasing demand for advanced technologies, sustainable solutions, and automation, mechanical engineers are playing a pivotal role in shaping the future.

Outstanding post, you have pointed out some good details , I besides conceive this s a very superb website.

Hi, i think that i saw you visited my web site thus i came to “return the favor”.I am trying to find things to enhance my site!I suppose its ok to use some of your ideas!!

Wonderful beat ! I would like to apprentice at the same time as you amend your site, how can i subscribe for a blog web site? The account aided me a appropriate deal. I had been a little bit acquainted of this your broadcast offered brilliant clear idea

Heya this is somewhat of off topic but I was wanting to know if blogs use WYSIWYG editors or if you have to manually code with HTML. I’m starting a blog soon but have no coding expertise so I wanted to get guidance from someone with experience. Any help would be enormously appreciated!

Well I sincerely enjoyed reading it. This article offered by you is very effective for proper planning.

I think other web site proprietors should take this website as an model, very clean and excellent user friendly style and design, as well as the content. You are an expert in this topic!

very good submit, i actually love this website, keep on it

You made some decent points there. I regarded on the web for the problem and found most individuals will associate with along with your website.

Hi, Neat post. There’s an issue along with your site in internet explorer, would test this?K IE still is the market leader and a good element of people will leave out your excellent writing due to this problem.